Clash Detection Challenge (Tight Spaces) [Case Study]

How 3D Laser Scan helped DMT Industrial Fabrication overcome one particularly challenging and unique obstacle

When DMT Industrial Fabrication was contracted to install a new piece of equipment in a food processing plant in Brooks, AB, they understood the magnitude of the job they were facing. The equipment, a multi-level platform which holds a Sweco separator on the top level, was designated for a tight space in a room already filled with a variety of equipment.

The Unique Challenge

For this particular project, it was crucial that the fabricated platform fit through a series of doorways and narrow spaces before reaching its final destination to be installed. This was where precise measurements were vital in ensuring everything fit well and there were no problems after fabrication was completed.

To make sure the job went smoothly, DMT brought in 3D Laser Scan to scan and model both the new equipment and the entire space.

“We had a tight timeline on this project and no room for errors. We were sending steel for galvanizing so we needed it to fit just right. Upon seeing the first proofs from 3D Laser Scan I knew we had made the right choice. The laser picked up the features of the operating technician’s face! Now that accuracy! We will be using this method on many projects to come. Extremely satisfied.”

– Barry Strom, DMT Industrial Fabrication.

Modelling the Equipment

The hand sketches provided to 3D Laser Scan

Our first step in ensuring precise fitment was to model the equipment as planned. We took the hand sketches and specifications provided by DMT Industrial Fabrication and modelled in a three-dimensional, virtual space to create a starting point with a firm idea of what the platform needs to be.

Our 3D model of the proposed equipment

Modelling the Space

The future home of the new equipment.

After the equipment was modelled, we brought our laser scanner to the site in Brooks and scanned the proposed area in just two hours. After uploading the scans back at our office, we processed the information and created a precise 3D model of the space.

Our 3D model of the space.

Interference Detection

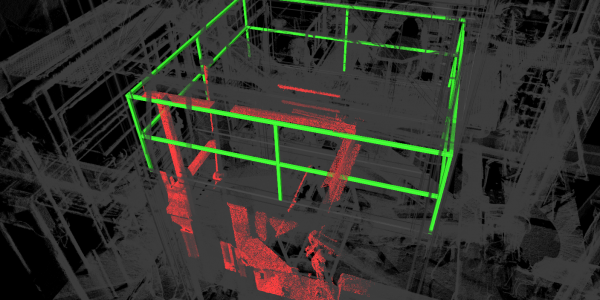

The new equipment modelled in place.

Within days of starting the project, we had both the equipment and space modelled and ready for their test fitting. When the two models were brought together in one virtual space through Navisworks Manage, we used clash detection to ensure proper fitment.

As depicted in the photos, we found various areas of interference that would have caused multiple headaches throughout the fitment process, saving DMT Industrial Fabrication time, money and manpower.

After discovering these problem-areas, we were able to minimize the changes required, provide a clear picture of each change, and create a plan before the site work began. All this while still optimizing the Sweco platform design for functionality in this very complex space. This gave DMT Industrial Fabrication the confidence that they could order a piece of equipment that could be installed without interference.

The interference areas (above) are shown in red

Revised model based on clash detection results

After running clash detection, we revised the model to better fit into the space. We verified that this would properly fit and created a new model with different dimensions. We determined how large of weldment we could prefab in the shop, while still fitting through the doorways into the plant. Each prefab section is coloured differently for visual representation. This allows for more of the project to be done in the shop, and less time required on site:

The final 3D model – colour coded to represented the different pieces to be fabricated in the shop

3D Laser Scan saved DMT Industrial Fabrication time, effort and money

3D Laser Scan was able to help DMT Industrial Fabrication find the most efficient solution so they could optimize their equipment within the space they were allotted. This allowed the entire project to proceed on budget and faster than the anticipated timeline, saving DMT Industrial Fabrication time, effort and money – and most importantly, allowing them to keep their client happy.

Let us help you take the guesswork out of your next industrial project.

Get a quote or request a demonstration from 3D Laser Scan today!